ҮЙЛЧИЛГЭЭ

Дело клиента

2018.9.14 This paper highlights a methodology for failure analysis of cast grinding ring of a ball and race mill. It investigates the root cause of premature failure of cast

узнать больше

2012.6.1 PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding

узнать больше

1981.7.1 Figure 1 shows a ball-and-race mill [1] in which heavily loaded balls roll in a rotating race, subjecting powder in the race to high crushing forces. Feed enters the

узнать больше

1982.9.1 The sub-models of comminution and classification for vertical spindle mill (VSM) presented in Part 1 of this paper have been integrated in the VSM simulation

узнать больше

2023.1.5 Adaptation of the Ball Race Mill Technology for Wet Comminution aiming to Reduce Energy Consumption by Jonathan Boon Chai Tan B.ASc., The University of

узнать больше

1982.9.1 An analysis of ball-and-race milling part II. The babcock E 1.7 mill. L.G.Austin P.T. Show more. Add to Mendeley. Share. Cite. Get rights and content.

узнать больше

An analysis of ball-and-race milling part III. Scale-up to industrial mills Semantic Scholar. DOI: 10.1016/0032-5910 (82)85046-8. Corpus ID: 108645472. An analysis of ball-and

узнать больше

2016.10.22 Investigation of Energy Consumed Characterization of Mixture Grinding in the Ball-and-Race Mill. Yaqun He, Weining Xie, Yong Yang, Hong Li, Shuai Wang Hua

узнать больше

Grinding Behavior of Coal Blends in a Standard Ball-and-Race Mill. Heechan Cho. 1995, Energy Fuels. Coal blending serves the purpose of controlling coal bulk characteristics

узнать больше

Part I. The hardgrove mill. L. G. Austin, J. Shah, +2 authors. P. Luckie. Published 1 July 1981. Materials Science. Powder Technology. View via Publisher. Save to Library.

узнать больше

2020.4.14 106809145-Ball-and-Race-Mill.pdf - Free download as PDF File (.pdf), Text File (.txt) or view presentation slides online. ... NTPC Limited ARRAMENT OF MILL PA FAN BALL RACE MILL (E

узнать больше

2018.9.14 The grinding ring was made of Ni Hard IV. Grinding ring of ball and race mill failed after giving the life only 2861 running hours. It was premature failure against the required useful life of 6500 running hours. The process of critical investigation of failure analysis includes visual observation, chemical analysis, microstructure analysis ...

узнать больше

3 天之前 The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter. Raw coal to be ground is fed from the ...

узнать больше

{"payload":{"allShortcutsEnabled":false,"fileTree":{"7":{"items":[{"name":"30 42 rock crusher occasion à vendre.md","path":"7/30 42 rock crusher occasion à vendre ...

узнать больше

2021.11.4 Ball-race mills and Loesche roller mills were used. Three types of interactions between mineral particles and grinding components, Fn-normal force, Ft-tangential force, m-mass, v-speed.

узнать больше

Mills. Raymond® Ball Race Mill. Get constant throughput of pulverized coal with capacities from 10 to 40 metric tons/hour. Low-maintenance design. a) Higher available grinding mass. b) Arrangement is such that most of the coal particles gets ground by rubbing of coal with coal particles instead of coal to metal contact. High availability.

узнать больше

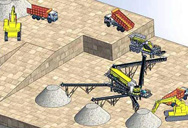

2021.4.30 Ball And Race Mills In this mill the coal passes between the rotating elements again and again until it has been pulverized to desired degree of fineness. The coal is crushed between two moving surfaces, namely, balls and races. The upper stationary race and lower rotating race driven by a worm and gear hold the balls between them.

узнать больше

1982.9.1 Austin et al. in their series of papers [6–8], analysed a ball-and-race mill and derived a detailed model based on a scale-up of the Hardgrove mill to an industrial mill. Neal et al. [9] performed a frequency analysis of mill and boiler complex, and analyzed its effects on the steam pressure. Show abstract.

узнать больше

2016.10.22 Based on the energy balance calculation of heterogeneous grinding, energy split factors (ESFs) of components in the ball-and-race mill at different grinding time are firstly computed. These two energies are calculated by the modified model with parameters in the mixture and single breakage, respectively.

узнать больше

The ball mill Ball milling is a mechanical technique widely used to grind powders into fine particles and blend materials. 18 Being an environmentally-friendly, cost-effective technique, it has found wide application in industry all over the world. Since this mini-review mainly focuses on the conditions applied for the preparation and ...

узнать больше

2022.1.29 Ball Bearing Types and Components. A ball bearing is a circular joint that connects a rotating part to another, usually stationary, part of a machine. It allows the rotating part to provide or receive

узнать больше

2015.3.1 The data provide details of coal circulation inside the VSM, which assisted the development of mechanistic models for a ball-race mill (E-mill), roller-race mill (MPS) and roller-race mill without air classifier (CKP mill). In the 1980s, the JKMRC developed the JKSimMet comminution simulation package for the minerals industry.

узнать больше

Walks the walk, talks the torque. Designed to deliver exceptional levels of performance and value, David Brown Santasalo ball mill drives are optimised for primary and secondary grinding applications. Extensively

узнать больше

2021.7.14 The more recent coal pulverizer designs are Vertical Roller Mills. 4. Ring-Roll and Ball-Race Mill Pulverizers A ball or roller between two races or rings provides the » Free Online Chat. Ball mill – Wikipedia, the free encyclopedia. The ball mill is a key piece of equipment for

узнать больше

The batch ball-race mill tests were conducted in a samples, and the blending ratio, as shown in Figure 2. standard Hardgrove machine. The grinding procedure of the However, this does not necessarily mean that the standard Hardgrove grindability test was followed, except that grinding system is linear, but only that it appears to narrowly sized ...

узнать больше

Ball and Race Mill (Figure 4.10): In the ball-and-race mill, balls are held between two races, much like a large ball bearing. The top race or grinding ring remains stationary while the bottom race rotates. As the coal is ground between large diameter balls and the ring, the balls are free to rotate on all axes and therefore remain spherical. ...

узнать больше

2015.3.1 MPS mill (roller-race) model. The most significant difference between the MPS and E-mill designs is the grinding mechanism. The MPS mill uses a three roller-race system instead of the 10 ball-race system deployed in the E-mill. The elutriator zone in the MPS mill also appears to be closer to the air classifier entry area.

узнать больше

1981.7.1 On the other hand, the types of mills where the kinetic model was less applied were planetary ball mills (for mica and dolomite) (Matijašic Glasnovic, 2009; Andrić et al., 2013), stirred ball mills (for quartz and nickel laterite) (Ma et al., 1998; Tong et al., 2013), and electromagnetic mill (for limestone) (Wołosiewicz-Głąb et al., 2019).

узнать больше

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, ... H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

узнать больше

2020.7.2 For this purpose, batch ball mill experiments were conducted with three narrow-size fractions (−3.35 + 2.36 mm, −1.70 + 1.18 mm, and −0.85 + 0.60 mm) of the feed and product samples of an ...

узнать больше

2013.12.6 Tube and ball mill Bowl Mill, Ball and Race mill Beater Mill, Impact Mill . 13 BOWL MILL Model no. Base capacity(T/Hr) 623XRP 18.4 703XRP 26.4 763XRP 33.8 803XRP 36.5 883XRP 51.1 903XRP 54.1 1003XRP 68.1 1043XRP 72.0 BASE CAPACITY(T/HR) AT HGI -55 Total Moisture-10% Fineness-70% THRU 200 MESH .

узнать больше

1982.9.1 It was demonstrated that the normalized primary fragment distribution produced in a pilot-scale Babcock E-type mill of 17 in. race diameter was the same as in the Hardgrove laboratory test mill and that the specific rates of breakage varied with particle size in the same manner. Steady-state continuous tests on the pilot-scale mill showed that ...

узнать больше

2018.6.1 Energy-size reduction experiments of particles in narrow and wide size were conducted in a modified ball-and-race mill, namely Hardgrove mill, with the addition of a power meter. Materials were SCC particles in size of 2.8–2 mm, 2–1.25 mm and 1.25–0.71 mm. SCC particles in neighboring size were mixed with mass ratios (coarse-to-fine) of 3 ...

узнать больше

1982.9.1 The crushing load, rotatiunat speed and mill shaft power of the Babcock E-type series of ball-race mills (3)_ power draw. The feed sizes to a large mill are chosen to give good crushing action in the race_ For coal they are normally a natural crushed size distribution with a top size of about 30 O. ... View PDF View article View in Scopus. 2. L ...

узнать больше

sbm ring and ball mill for pulverisation of coal pdfImproving Coal Pulverizer Performance and Reliability Ring Roll and Ball Race Mills A ball or roller between two ...

узнать больше

2022.1.19 Ball mill Most ball mills, even in primary applications, have a finer ore feed size; this requires some impact but not enough to increase the media consumption or even break the liners. Typically, a ball mill lining has a more rounded profile, often like a sine wave, and the size of the waves is selected based on the size of grinding media used.

узнать больше

Contribute to chengxinjia/sbm development by creating an account on GitHub.

узнать больше

2018.9.15 Ball and race mill is a mechanical device used for pulverizing the coal for combustion in boilers of thermal power plants. The ball and race mill consists of a lower grinding ring connected to the drive assembly through a mechanical part yoke and stationary upper grinding ring with the application of pressure from set of springs situated on the

узнать больше

Download Free PDF. Grinding Behavior of Coal Blends in a Standard Ball-and-Race Mill. Grinding Behavior of Coal Blends in a Standard Ball-and-Race Mill. Heechan Cho Cho. 1995, Energy Fuels. See Full PDF Download PDF.

узнать больше

2014.10.28 Ball and Race Mill; of 76 /76. Match case Limit results 1 per page. Ramagundam Super Thermal Power Station NTPC Limited Ball Race mill Namendra Anand Sr. Engineer (BM/RM) Ramagundam Super Thermal Power Station NTPC Limited [email protected] Author: sandeep19861986. Post on 28-Oct-2014. 139 views. Category:

узнать большеузнать больше